Industrial IoT: Building Remote Monitoring Systems

Table of Contents

Lauch your IoT product in few weeks for MVP

Learn more

Industrial IoT: Building Remote Monitoring Systems

Industrial IoT (IIoT) has moved from buzzword to boardroom priority, transforming how factories, utilities, and process industries see, understand, and optimize their operations. At its core, remote monitoring IoT connects sensors, machines, and software into an intelligent system that continuously collects data, analyzes it in real time, and triggers actions that improve safety, efficiency, and uptime. When implemented well, industrial IoT development delivers tangible outcomes: fewer breakdowns, lower maintenance costs, tighter quality control, and a smarter, more agile operation.

This guide dives deep into building robust, secure, and scalable industrial IoT solutions for remote monitoring. You will find practical architecture patterns, technology choices, security guardrails, and an implementation roadmap, along with case studies and evaluation criteria for choosing platforms and partners. We also explore how a smart factory dashboard becomes the nerve center of operations, turning raw signals into decisions.

Key topics we cover:

- What remote monitoring in IIoT really entails and why it matters.

- Core components: sensors, connectivity, edge, cloud, analytics, and user interfaces.

- Business value, from predictive maintenance IoT to cost savings and compliance.

- Real-world challenges and how to mitigate them.

- An architecture blueprint and technology stack for scale.

- Security-by-design and governance.

- Implementation steps from pilot to enterprise rollout.

- Case studies and open-source options.

- How to select the right industrial IoT solutions and vendors.

- Future trends: 5G, digital twins, edge AI, and more.

Whether you are modernizing legacy assets, deploying a greenfield smart line, or connecting remote infrastructure across regions, the principles here will help you build a resilient remote monitoring IoT foundation that supports today’s operations and tomorrow’s growth.

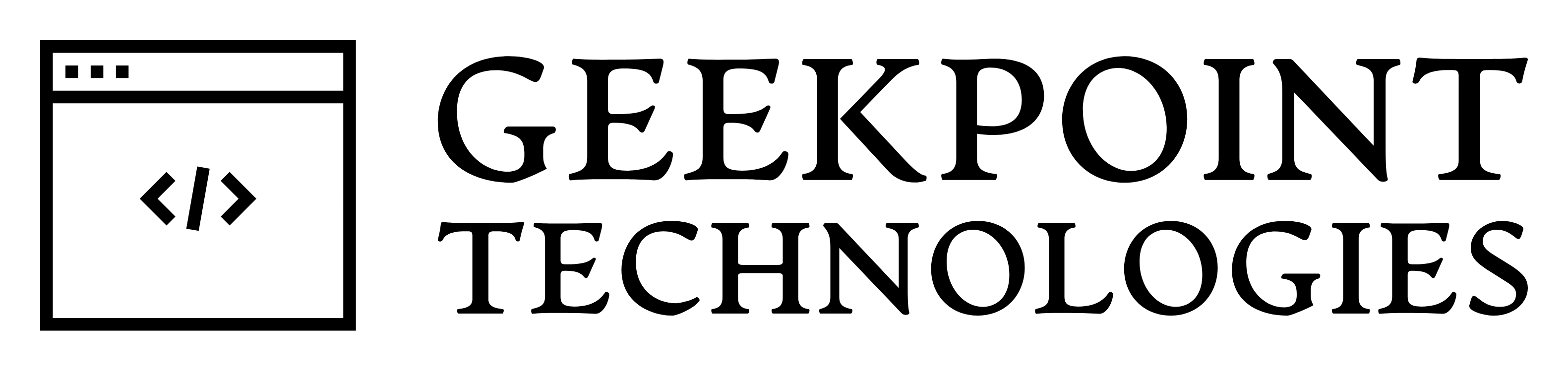

What Remote Monitoring in IIoT Means: Components That Make It Work

Remote monitoring in IIoT is the continuous observation of equipment, processes, and environmental conditions via connected sensors and systems, regardless of physical location. Data is captured at the edge, transmitted over reliable networks, processed for insights, and visualized on a smart factory dashboard for fast, informed decisions. The value is in closing the loop: detect, analyze, decide, act.

Core components of an effective remote monitoring IoT stack:

- Sensors and actuators: From vibration, temperature, current, and pressure sensors to control relays and valves. Choose industrial-grade devices (IP-rated, extended temperature range) with calibration traceability.

- Industrial control layer: PLCs, RTUs, and DCS provide deterministic control. Modern architectures non-intrusively tap these controls for telemetry using OPC UA or native drivers.

- Edge gateways and data processing: Gateways normalize data (Modbus, Profibus, CAN, proprietary), buffer during outages, run local analytics (FFT for vibration), and publish securely (MQTT Sparkplug B or AMQP).

- Connectivity: Wired Ethernet for reliability on the floor; wireless such as Wi‑Fi 6/6E for local mobility; LPWAN (LoRaWAN) or cellular (LTE-M, NB-IoT, 4G/5G) for remote assets; private 5G for high-density, low-latency use cases.

- Cloud/Datacenter platforms: Time-series databases, stream processors, data lakes, and ML services. Hybrid models retain sensitive data on-prem and burst analytics to the cloud.

- Applications and dashboards: Role-based views for operators, maintenance, quality, and management. The smart factory dashboard consolidates KPIs, trends, alerts, and work orders.

When stitched together via open standards, these components form resilient industrial IoT solutions that scale from a single line to global fleets.

Business Impact: Why Remote Monitoring Is the New Industrial Baseline

Organizations adopt industrial IoT development not just to collect data, but to drive measurable improvements. Here’s how remote monitoring IoT delivers value across the plant and beyond:

Operational efficiency

- Real-time visibility reduces response times from hours to minutes.

- Bottleneck detection and energy optimization cut waste in utilities (compressed air, steam).

Predictive maintenance IoT

- Condition-based monitoring (vibration, thermography, oil analysis) predicts failures before they cascade.

- ML models forecast remaining useful life, enabling planned downtime and spare parts readiness.

Quality and throughput

- In-line analytics catch drift early, minimizing scrap and rework.

- Recipe and process parameter compliance is enforced automatically.

Safety and compliance

- Continuous gas, noise, or temperature monitoring flags hazards.

- Automated audit trails simplify ISO/IEC and industry compliance.

Cost savings and ROI

- Fewer truck rolls for remote sites and reduced manual inspection.

- Lower inventory through just-in-time maintenance.

- Reduced warranty/recall exposure via traceability.

Workforce enablement

- A unified smart factory dashboard reduces screen hopping across SCADA, CMMS, and MES.

- Mobile alerts bring actionable context to technicians on the floor.

These outcomes compound. A 1–2% availability gain multiplied across critical assets often pays for the entire program. The key is aligning IIoT metrics with business KPIs—OEE, MTBF, energy per unit, and first-pass yield—so improvements are visible and sustained.

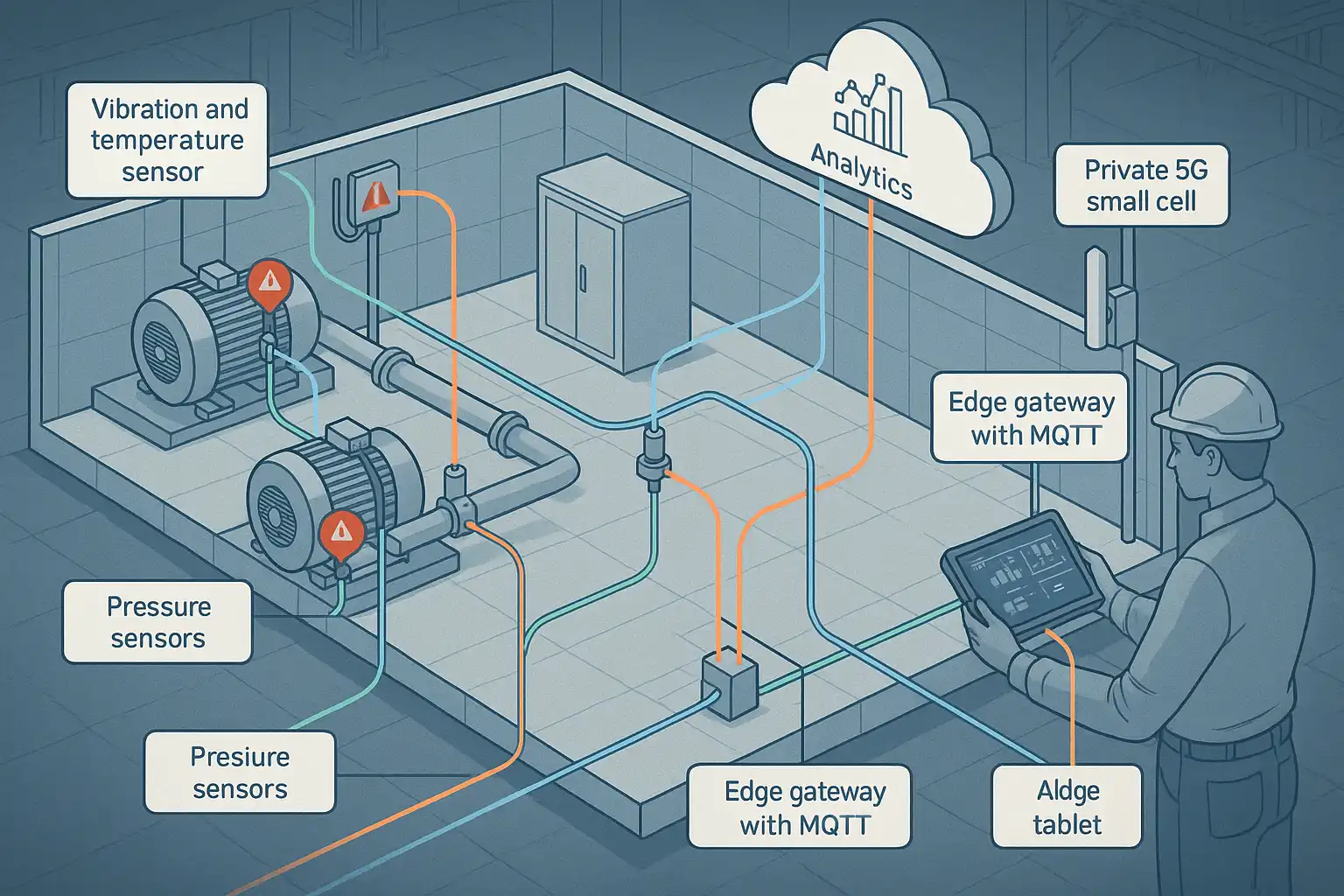

Challenges and How to Overcome Them in IIoT Deployments

Industrial environments bring unique constraints—legacy systems, harsh conditions, strict safety rules. Successful industrial IoT solutions anticipate and mitigate challenges from the outset.

Top challenges and practical mitigations

1) Data security and cyber risk

- Risks: Unauthorized access to control networks, ransomware, data exfiltration.

- Mitigations: Network segmentation (ISA/IEC 62443 zones and conduits), zero-trust access, mutual TLS, device identity (X.509), hardware root of trust, and continuous vulnerability management.

2) Integration with legacy systems

- Risks: Proprietary protocols, limited compute on PLCs, fear of production impact.

- Mitigations: Non-intrusive data taps, protocol converters, OPC UA wrappers, and digital replicas of tags to avoid touching validated logic.

3) Scalability and reliability

- Risks: Message storms, schema drift, data quality issues as fleets grow.

- Mitigations: MQTT with Sparkplug B for stateful sessions, schema registries, store-and-forward buffers, and SLOs for data latency and availability.

4) Data management and analytics

- Risks: Data lakes turning into data swamps; difficult model lifecycle.

- Mitigations: Curated time-series stores, event-driven pipelines, feature stores, and MLOps (versioning, drift detection, rollback).

5) Organizational alignment

- Risks: IT/OT silos, unclear ownership, skills gaps.

- Mitigations: Joint governance, RACI across IT/OT/EHS/Maintenance, training, and change management.

The path forward is phased: start small with a high-value asset, validate security and performance, then standardize patterns for wider rollout. Documented reference architectures, pre-approved device catalogs, and reusable pipelines are the force multipliers.

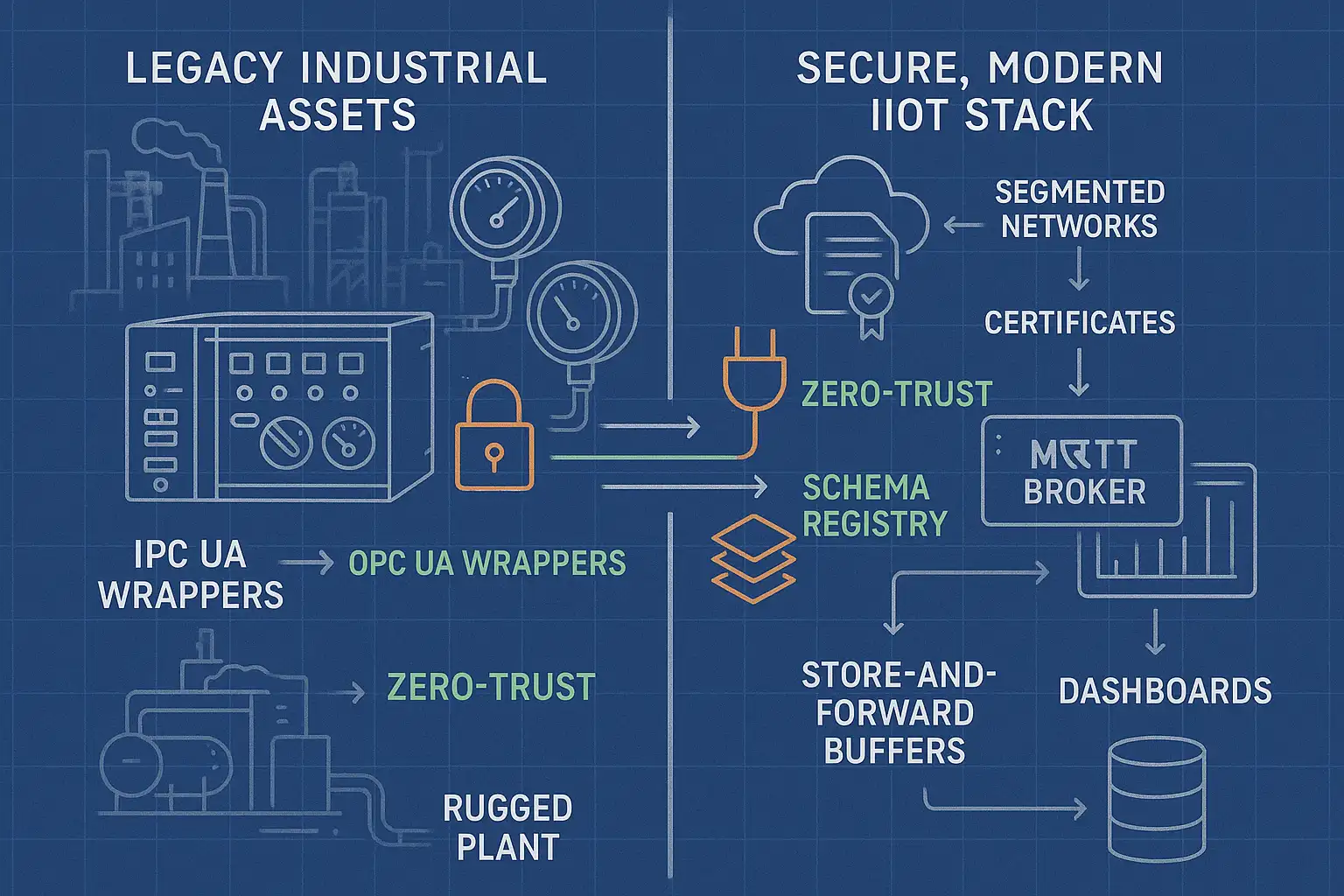

Architecture Blueprint: From Sensor to Smart Factory Dashboard

A robust architecture links operational technology (OT) with information technology (IT) without compromising safety or performance. Below is a reference blueprint you can adapt.

Layers overview

- Field layer: Sensors (IEPE accelerometers, RTDs, pressure transducers), actuators, and legacy instruments.

- Control layer: PLCs/RTUs and safety systems (kept deterministic and isolated).

- Edge layer: Industrial PCs/gateways running protocol translation, filtering, and analytics (FFT, envelope analysis, thresholds).

- Data transport: MQTT over TLS with Sparkplug B for stateful session management; alternative paths via AMQP or HTTP for bulk.

- Platform layer: Time-series DB (e.g., InfluxDB/Timescale), stream processing (Kafka/Flink), data lake for historical and ML, and a metadata catalog.

- Application layer: Smart factory dashboard with role-based views, alerting, and workflow integrations (CMMS, MES, ERP).

Event flow example 1) A vibration sensor detects an increase in RMS velocity. 2) Edge gateway runs an FFT, flags a bearing fault signature. 3) Message published to MQTT broker with asset ID, severity, and evidence (spectral peaks). 4) Stream processor enriches with maintenance history and shifts. 5) Predictive maintenance IoT model calculates remaining useful life. 6) Dashboard presents an alert with recommended action; CMMS auto-creates a work order.

Key design tips

- Treat the edge as a first-class analytics tier to reduce bandwidth and latency.

- Enforce data contracts; version schemas and tag taxonomies.

- Build graceful degradation: store-and-forward and local HMI fallbacks.

- Keep control loops in the control system; monitoring stays read-only unless governed by change control.

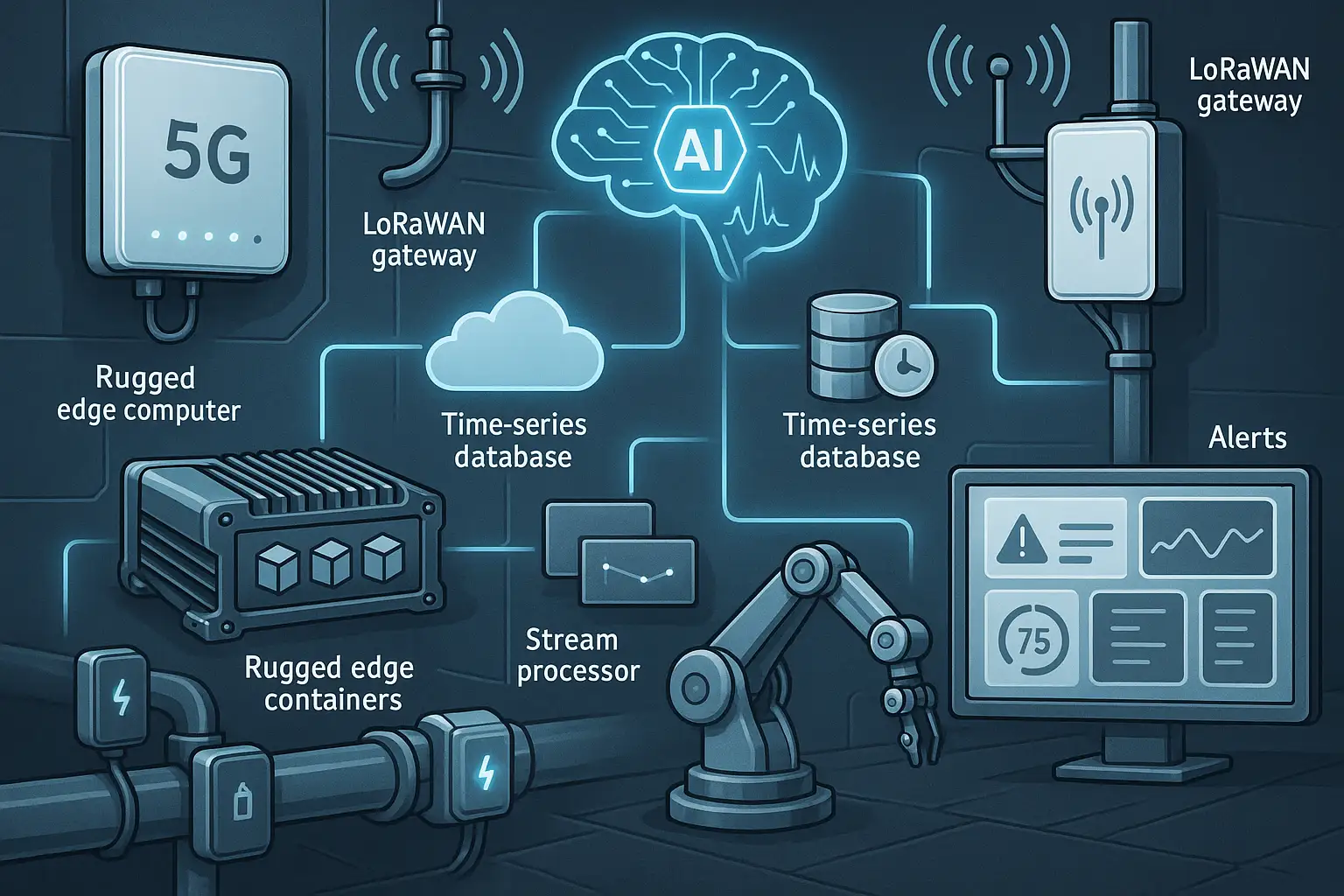

Technologies Powering Remote Monitoring: Connectivity, Edge, Cloud, and AI

Choosing the right technologies determines scalability, cost, and reliability. Blend them to fit your environment and constraints.

Connectivity options

- LoRaWAN: Long range, low power for dispersed sensors (tanks, pipelines). Ideal for battery-operated nodes with intermittent uplinks.

- Sigfox and private LPWAN: Niche alternatives for ultra-low throughput.

- Cellular (NB-IoT, LTE-M): Deep indoor coverage with power-saving modes; good for mobile and remote assets.

- 4G/5G and private 5G: High density, QoS, and low latency for video, AGVs, and time-sensitive telemetry.

- Wi‑Fi 6/6E and Ethernet: High throughput in plant environments; deterministic Ethernet variants for control networks.

Edge computing

- Micro-batching, compression, and anomaly detection at the edge reduce costs and protect uptime.

- Containers on industrial PCs allow standardized deployment of analytics and protocol services.

- Use GPU/accelerators only where needed (e.g., vision-based inspection).

Cloud and hybrid platforms

- Time-series optimized storage plus object storage for raw payloads.

- Stream processing for real-time alerts; batch processing for trend and model training.

- Hybrid patterns keep control data on-prem while leveraging cloud scale for AI.

AI and ML for predictive maintenance IoT

- Feature engineering (spectral bands, kurtosis, crest factor) powers fault classification.

- Semi-supervised learning and anomaly detection help when labels are scarce.

- MLOps is non-negotiable: version data, models, and pipelines; monitor drift and retrain.

Visualization and orchestration

- A smart factory dashboard surfaces KPIs, alarms, and recommended actions by role.

- Low-code interfaces accelerate app creation while APIs keep the system open.

Together, these building blocks create resilient industrial IoT solutions that adapt to evolving needs without locking you in.

Security by Design: Protecting People, Processes, and Data

Security is foundational in industrial IoT development. The goal is to improve visibility without increasing risk. Adopt a defense-in-depth strategy aligned with OT realities.

Core principles

- Zero trust: Authenticate and authorize every device, user, and workload. Enforce least privilege and just-in-time access.

- Segmentation: Separate safety/control networks from monitoring networks; use firewalls and data diodes where necessary.

- Strong identities: Unique device credentials (X.509), certificate rotation, and secure boot.

- Encryption: TLS 1.2+ in transit; encrypted volumes at rest with key management.

- Patch and update strategy: Staged rollouts, maintenance windows, and SBOM tracking.

Monitoring and response

- Collect telemetry from gateways, brokers, and apps to a SIEM; baseline behavior to detect anomalies.

- OT-aware IDS can spot protocol misuse or rogue devices.

- Incident response plans must consider physical safety and production continuity.

Compliance and governance

- Map controls to ISA/IEC 62443, NIST 800-82, and sector regulations.

- Data residency and retention policies for time-series and logs.

- Regular tabletop exercises with IT/OT/EHS participation.

Practical tips

- Prefer read-only mirrors for production data; make write paths explicit, audited, and approved.

- Use tokenized access to APIs; avoid embedding long-lived secrets in devices.

- Test backups and broker failover. A secure system is also a recoverable system.

Security is never ‘done’. Build it into backlog, budgets, and KPIs—mean time to detect, patch compliance, and recovery readiness.

Implementation Roadmap: From Pilot to Enterprise Scale

Successful programs are iterative. A structured approach reduces risk, surfaces value early, and builds momentum across sites.

1) Discover and align

- Define business goals: reduce unplanned downtime by x%, improve OEE, cut energy by y%.

- Inventory assets, data sources, and constraints. Identify quick wins and high-risk items.

2) Design a reference slice

- Pick one line or asset family. Define data model, security controls, and SLAs.

- Choose connectivity and edge stack based on environment (noise, temperature, coverage).

3) Pilot and validate

- Instrument assets, set up the MQTT broker and time-series store, and configure the smart factory dashboard.

- Validate data quality, alert thresholds, and latency targets. Run failure mode simulations when safe.

4) Prove value

- Quantify maintenance reductions and throughput gains. Tie alerts to actual work orders and downtime events.

- Document lessons, refine playbooks, and update device catalogs and schemas.

5) Scale out

- Standardize templates for gateways, topics, and dashboards. Automate provisioning with IaC and device onboarding.

- Establish MLOps for predictive maintenance IoT models: CI/CD, feature stores, monitoring, retraining.

6) Operate and improve

- Create a runbook for support and incident response. Track KPIs and user feedback.

- Expand use cases: energy optimization, quality analytics, and sustainability reporting.

Dependencies to plan for

- Network coverage and bandwidth constraints.

- Change control windows for production environments.

- Integration with CMMS, MES, ERP, and identity providers.

The outcome is a repeatable engine that deploys industrial IoT solutions reliably across sites and geographies.

Case Studies: Water Networks and Industrial Equipment Monitoring

Real-world implementations showcase how remote monitoring IoT translates into results.

Water distribution networks

- Challenge: Wide-area infrastructure with limited power and diverse equipment.

- Solution: Wireless sensing for flow, pressure, and reservoir levels; edge aggregation at pump stations; cloud analytics for leak detection and demand forecasting.

- Outcome: Faster leak localization, reduced non-revenue water, and optimized pump schedules that cut energy costs.

- Example: CiTop-IoT’s wireless monitoring for water distribution delivers real-time data collection and control across dispersed assets. Learn more at citop-iot.com.

Industrial equipment monitoring

- Challenge: Mixing CNCs, presses, and legacy machines with varying protocols.

- Solution: Gateways normalize data (OPC UA/Modbus), MQTT publishes to a broker; dashboards surface OEE, downtime reasons, and predictive maintenance IoT alerts.

- Outcome: Unified visibility and 10–20% reductions in unplanned downtime after six months.

- Example: OpenRemote provides an open-source platform connecting machines to the cloud for real-time monitoring and maintenance insights. Explore at openremote.io.

Key takeaways

- Start with measurable pain points (leaks, downtime) and choose connectivity that matches geography and power constraints.

- Edge processing reduces data costs and latency while increasing resilience.

- Open architectures prevent lock-in and facilitate incremental upgrades.

These examples highlight the breadth of industrial IoT development—from municipal utilities to discrete manufacturing—proving that scalable, secure industrial IoT solutions are achievable today.

Selecting the Right IIoT Remote Monitoring Solution

With a crowded market, choosing platforms and partners can be daunting. Use these criteria to evaluate industrial IoT solutions for remote monitoring IoT at scale.

Technical fit

- Compatibility: Drivers for your PLCs/RTUs, support for OPC UA and MQTT Sparkplug B, and flexible data modeling.

- Edge capability: On-device analytics, store-and-forward, secure remote management.

- Connectivity breadth: Ethernet, Wi‑Fi, LPWAN, cellular, and private 5G options.

- Integration: APIs, webhooks, and connectors for CMMS, MES, ERP, and identity providers.

Security and compliance

- Built-in identity, encryption, RBAC/ABAC, and audit logging.

- Alignment with ISA/IEC 62443 and relevant sector standards.

Usability and adoption

- A smart factory dashboard that is role-based, customizable, and mobile-friendly.

- Alerting with context (evidence, recommended actions) and noise reduction controls.

Scalability and reliability

- Proven multi-site deployments, high-availability brokers, and global device management.

- Schema management, topic conventions, and multi-tenant isolation if needed.

Economics and support

- Transparent pricing: device, message, storage, and analytics costs.

- Vendor viability, roadmap alignment, and SLAs.

- Professional services and community ecosystem (especially for open-source stacks).

Decision tips

- Run a proof-of-value against your real data and constraints.

- Avoid lock-in by preferring open standards and exportable data.

- Prioritize time-to-value: choose stacks that deliver early wins while supporting long-term growth.

The right platform accelerates industrial IoT development while keeping your architecture portable and secure.

Future Trends: 5G, Digital Twins, and Autonomous Operations

The next wave of industrial IoT solutions is shaped by faster networks, richer models, and smarter automation. Planning for these trends protects today’s investments and unlocks new value.

5G and time-sensitive networking

- Private 5G brings reliable, deterministic wireless for mobile robots, AR-assisted maintenance, and high-density sensors.

- TSN bridges OT determinism with IT flexibility, enabling tighter monitoring-control loops where appropriate.

Digital twins

- Asset and process twins mirror real-world behavior for simulation, what-if analyses, and prescriptive maintenance.

- When fed by remote monitoring IoT data, twins can forecast performance under varying loads and environments.

Edge AI and computer vision

- Running models at the edge reduces latency and bandwidth—ideal for defect detection, PPE compliance, and safety zones.

- Federated learning helps keep sensitive data local while models improve globally.

Trust and data integrity

- Blockchain and secure logging can verify provenance and tamper evidence for quality and compliance use cases.

Sustainability analytics

- Continuous monitoring of energy, emissions, and waste supports net-zero commitments and ESG reporting.

Autonomous operations

- Closed-loop systems propose—and in governed contexts, execute—optimal setpoint changes based on constraints and objectives.

The smart factory dashboard of the near future becomes a command center for hybrid human-machine decision-making, where predictive maintenance IoT insights, quality analytics, and energy optimization converge into a coherent operational picture.

Conclusion: Build a Resilient, Scalable Remote Monitoring Foundation

Industrial IoT development has matured from experimentation to essential infrastructure. By combining rugged sensors, secure connectivity, capable edge computing, scalable data platforms, and a clear operational vision, you can deliver remote monitoring IoT that improves uptime, quality, and safety—while controlling costs.

Key takeaways

- Start with business goals and use cases tied to OEE, MTBF, energy, and quality.

- Use open standards (OPC UA, MQTT Sparkplug B) and layered security (ISA/IEC 62443) from day one.

- Treat the edge as a critical analytics tier; adopt MLOps for predictive maintenance IoT.

- Consolidate insights into a smart factory dashboard that serves multiple roles without overwhelming users.

- Scale with governance: standardized schemas, device catalogs, and deployment automation.

With thoughtful planning and the right industrial IoT solutions, your organization can turn data into decisions and decisions into sustained performance. The factories, utilities, and infrastructure leaders of the next decade will be those who build dependable remote monitoring foundations today—and continuously evolve them as technology and business needs change.

Looking for an IoT app development partner?

Are you looking for a reliable partner to help you build a stunning IoT companion app? You're in the right place.

We have 6+ years of experience building a variety of IoT apps, from healthcare to HVAC. So, if you go with us, you'll be in safe hands.

If you want to learn more, feel free to reach out and our team will be happy to set up a call to discuss your needs in more detail.

Get in touch